A204 Battery Labeler

A204 is an ideal and economical solution for battery industry to labeling on the No.5 & No.7 batteries. Automatic downloading device and roller conveyor belt get the battery feeding, conveying, labeling, heat shrink finished without any letup. The system can be used either stand-one, or integrated easily into the existing production line. The roller conveyer and label adapting belt mechanism both adopt stepless regulating transducer and the heat shrink device matching with the labeling speed, resolves various labeling problems such as crinkle, frothy and miss-position, etc.

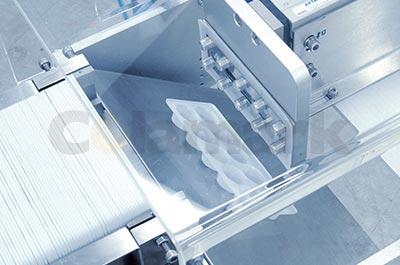

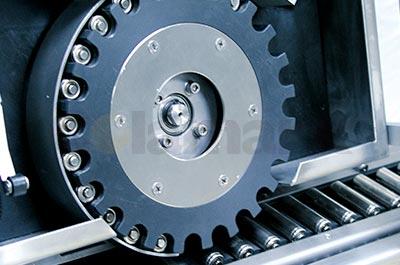

- Easy changeover for different battery sizes: Just change the separating wheel to swap between No.5 and No.7 batteries.

- Use of through-beam photo-sensors for material level detection. Achieve automatic speed adjustment at low material level, and automatic stop when no material.

- Automatic suspension of labeling process when the shrink tunnel is over-heated or under-heated avoiding label wastage from improper heat shrinking.

- Automatic temperature control of the shrink tunnel for good protection:

- Adjustable temperature and blowing intensity for optimal labeling effect.

- When the conveyor is stopped for a prescribed duration, the shrink tunnel will automatically stop heating to avoid overheating the two ends of the batteries in the tunnel.

- When the conveyor is stopped completely, the shrink tunnel will stop heating and blowing

- Optional polarity detection feature: Automatically detects batteries placing in wrong polarity orientation and rejection.

- Double safety features at the feeding mechanism: torque detection and emergency stop. When a mis-located battery blocks the star wheel, the machine will stop automatically.

- Features for effective prevention of the problems such as missed labeling, wrong position, and double labeling; include intelligent label quantity management, warning messages and optional visual inspection devices.

| Model: | A204 |

| Name: | Battery Labeler |

| Capacity: | 350pbm |

| Weight: | 350kg |

| Electricity: | 220VAC±10% 50Hz 2.6kW |

| Dimension(for reference): | (L)2,580×(W)680×(H)1,650 mm |

| Please select the PDF file link for specification detail after sign in. | |

Horizontal Wrap-around,Battery

Vials/Ampoules ,round labeling,Round bottles,Vertical Wrap-around,Vial/Ampoule

Battery Labeling System

A204R is an ideal high labeling solution for automatic wrap-around lab......

View detailsHigh Speed Horizontal Tray Inserter

RH1 is specifically designed for the bottle packaging process of the p......

View detailsHigh Speed Horizontal Labeling and Tray Insertion Solution

A205R is the perfect integration of the A205 High Speed Vial Labeling ......

View detailsLipstick end face intelligent labeling machine

A109HT is the latest product of dahlgar applied to lipstick end face l......

View detailsLipstick Labeling System

A109 is specially designed for high precision labeling on the end of l......

View detailsVertical Feeding Horizontal Wrap-around Labeling System

A205 is specially designed for high speed and precision labeling on am......

View detailsHorizontal Tray Feeder

TS1 Horizontal Tray Feeder is designed for the packaging process of ph......

View detailsHorizontal Labeling System for Prefilled Syringes

A210 is a flexible labeling system for pre-filled syringes and other n......

View details