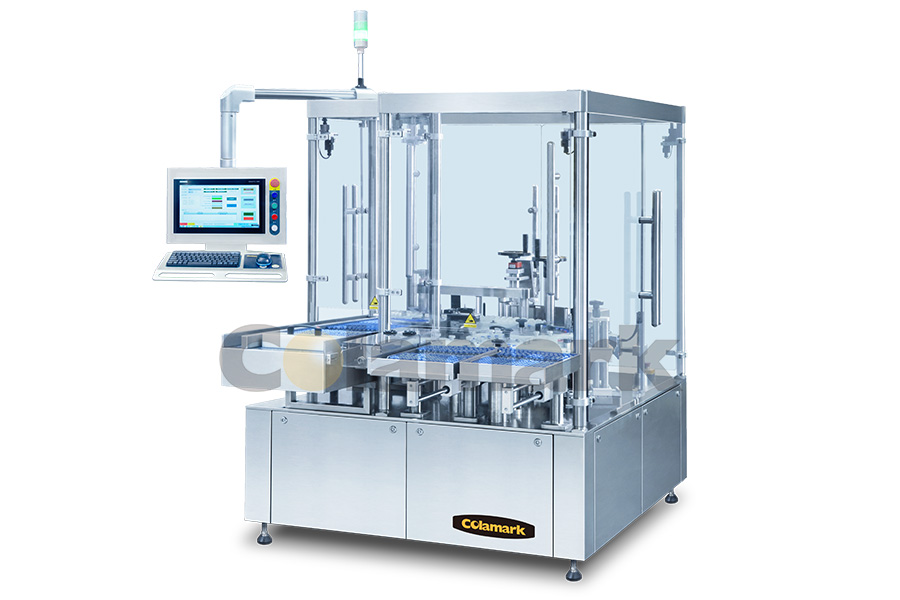

A105 Vertical Labeling System with Rotary Table for Ampoules

A105 is specially designed for high speed and precision labeling on ampoules, vials, and other thin pharmaceutical bottles that cannot stand stably for transport. Tray-to-tray operation and spacing worm for convenient standalone operation. Rotary indexing table aligns bottles at three points enabling extra stability and high precision labeling at all speeds. Unique mechanism effectively avoids bottle breakage thus allows smooth operation at very high speed. Optional label and code inspection. Patented positive drive rejection wheel mechanism ensures accurate rejection of defective products orderly during high speed operation.

- Vertical transportation of bottles in the full cycle. Good also for thin bottles that cannot stand stably by itself for transportation.

- Use of rotary turntable and feeding worms throughout the path for bottle movement and indexing to ensure bottle movement stability.

- Properly indexed bottle position to ensure inspection and rejection consistence.

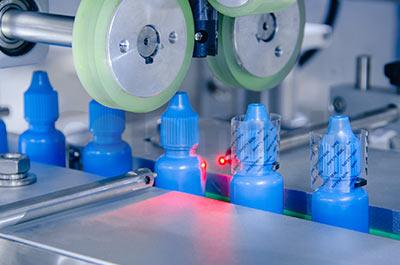

- Various optional inspection devices including missing code detection, missing label detection, visual system inspection for label content and placement accuracy etc.

- Rejection device at fully indexed pace to ensure accurate rejection at high operation speed.

- Bottle is gripped at 3 points at labeling to ensure proper alignment between bottle and label.

- Tray-to-tray operation mode - Loading bay and discharge bays located in the same side for easy operator handling.

- Optional in-line operation mode. The large bottle buffer at the loading bay allows smooth connection with upstream equipment.

- Connects seamlessly to the Colamark tray insertion machines for tray insertion of the labeled bottles - another step of integrated automation at your packaging line.

- High speed operation at up to 600 bpm.

- Optional high speed hot stamping coder or thermal transfer overprinter at matching speed.

- Safety enclosure and safety door switches.

- PLC controlled operation.

- User friendly HMI with program memory.

| Model: | A105 |

| Name: | Vertical Labeling System with Rotary Table for Ampoules |

| Capacity: | 600pbm |

| Weight: | 600kg |

| Electricity: | 220VAC±10% 50Hz 4.1Kw |

| Dimension(for reference): | (L)2,050×(W)1,630×(H)1,990 mm |

| Please select the PDF file link for specification detail after sign in. | |

Vial/Ampoule,Vertical Wrap-around

Vials/Ampoules ,round labeling,Round bottles,Vertical Wrap-around,Vial/Ampoule

5 Gallon Pail Wrap Around Labeling System

Designed for wrap around labeling on 5 gallon pails. Featured with reg......

View detailsRotary Vertical Round Bottle Labeling System

A103 is designed for high precision labeling on small pharmaceutical b......

View detailsShrink Sleeve Labeling System

An ideal and economical choice for the packagers to automatically inse......

View detailsLipstick end face intelligent labeling machine

A109HT is the latest product of dahlgar applied to lipstick end face l......

View detailsHigh Speed Horizontal Labeling and Tray Insertion Solution

A205R is the perfect integration of the A205 High Speed Vial Labeling ......

View detailsBattery Labeling System

A204R is an ideal high labeling solution for automatic wrap-around lab......

View detailsHigh Precision Front/Back & Orientation Wrap-around Labeling System

Using a synchronized swing-hand secondary alignment mechanism to ensur......

View detailsPrefilled Syringe Assembly & Labeling System

A11 is an award winning prefilled syringe plunger-rod assembling and s......

View details