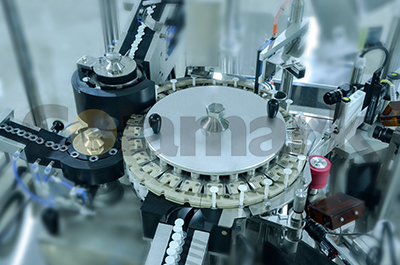

A11 Prefilled Syringe Assembly & Labeling System

Prefilled Syringe Assembly & Labeling SystemVideo

please login to watch video.

A11 is an award winning prefilled syringe plunger-rod assembling and syringe labeling machine.

A11 a modular design labeling system with functions such as Track and trace; label print inspection, label present check, plunger rod and needle cap in position check.

A11 a modular design labeling system with functions such as Track and trace; label print inspection, label present check, plunger rod and needle cap in position check.

A11 can connect with semi-automatic de-nester or DN1 Denester for automatic syringe infeed.

- Over 70 lines installed in Asia, Europe and Middle East

- Various coding devices available for synchronized online coding at high speed: hot stamping, thermal transfer overprinting, inkjet or laser

- Syringes infeed from denester, plunger-rod supply by hopper with singulating device.

- Siemens PLC controlled. Siemens Win CC OS and 21CFR 11 are options.

- Various inspection options are also available to detect missing label, missing code, wrong code, missing plunger-rod etc. Defective syringe are automatically collected in a rejection tray.

| Model: | A11 |

| Name: | Prefilled Syringe Assembly & Labeling System |

| Capacity: | 200pbm |

| Weight: | 600kg |

| Electricity: | 220VAC±10% 50Hz 2kW |

| Dimension(for reference): | (L)1,580mm x (W)1,410mm x (H)2,370mm |

| Please select the PDF file link for specification detail after sign in. | |

Plunger-rod Assembly & Labeling System for Prefilled Syringes

Vials/Ampoules ,round labeling,Round bottles,Vertical Wrap-around,Vial/Ampoule

Related Equipment

PFS High Speed Labeling & Plunger Assembly System

A33 designed for 400PPM high speed labeling on the prefilled syringe a......

View detailsHorizontal Labeling System for Prefilled Syringes

A210 is a flexible labeling system for pre-filled syringes and other n......

View detailsHopper – PFS Plunger Rod / Safety Device

Colamark plunger/ safety Device Hopper can fully integrated with our P......

View details