A410RV Intelligent Labeling Machine with Robotic Vision Positioning

The Colamark A410RV redefines production line efficiency through fully automated operation. Equipped with high-precision vision positioning and a flexible robotic arm, it achieves ±2mm level precision labeling, compatible with various bottle sizes, boxes, and irregular packaging. It can also be optionally combined with a real-time online printing system to instantly print QR codes, production dates, barcodes, graphics, and product-related information. Additionally, it can be used in conjunction with the Colamark traceability system to achieve product traceability. It is suitable for a wide range of industry scenarios, including food, pharmaceutical, and daily chemical industries, and helps enterprises complete the intelligent upgrade of the packaging process.

Automation and Efficiency

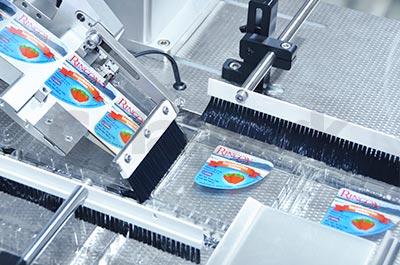

The entire process is unmanned, with robotic arms, conveyors, and sensors working in coordination to achieve integrated operations of automatic feeding, positioning, labeling, and inspection.

High-speed production with a conveyor belt speed of 15 meter/min., significantly higher than manual efficiency, suitable for large-scale assembly line operations.

Precision and Adaptability

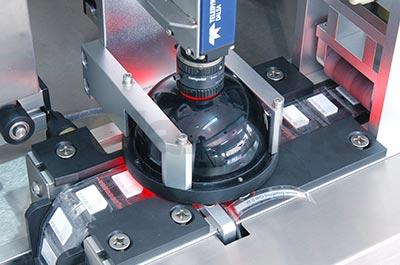

High-precision positioning with a vision recognition system, error ≤±2mm, adaptable to complex scenarios.

Multi-specification compatibility: by quickly changing fixtures or programs, it can handle products of different sizes (such as bottles, boxes, and tubes) and label types (such as adhesive labels, RFID, etc.).

Reliability and Safety

HMI operation is convenient, intuitive, and features rich help functions and fault display functions.

Intelligent control with automatic detection of label length and alarm for remaining labels.

Intelligent Labeling Machine with Robotic Vision Positioning

Intelligent Labeling Machine with Robotic Vision Positioning

Stand-alone labeling machine

For automatic labeling on products or packaging on the production line......

View detailsFront Side Labeling System with Re-orientation for Square-wrapping

A910R is a multi-function labeling system for side labeling on oval or......

View detailsLipstick end face intelligent labeling machine

A109HT is the latest product of dahlgar applied to lipstick end face l......

View detailsSmart Top Labeling Machine

Versmark is a versatile system for the personalization of thin product......

View detailsCartoning Machine

Bravo is the best value cartoners in the market.BRAVO is a balco......

View detailsMini SIM Card Wrapping and Cartoning System

Mini SIM Card Wrapping and Cartoning System Simpak is designed for wra......

View detailsHigh Speed Servo Cartoning System

Bravo 150 is a fully servo controlled cartoning system with advantages......

View details