Pre-Filled Syringe packing line

This PFS packing line is designed for a leading Bio-tech company. Colamark supplied more than 50 lines worldwide including China, India, Indonesia, Korea, Turkey, United Kingdom.

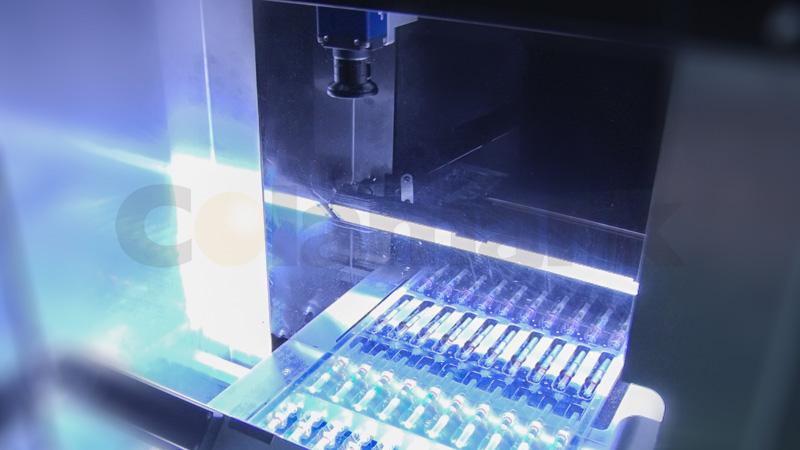

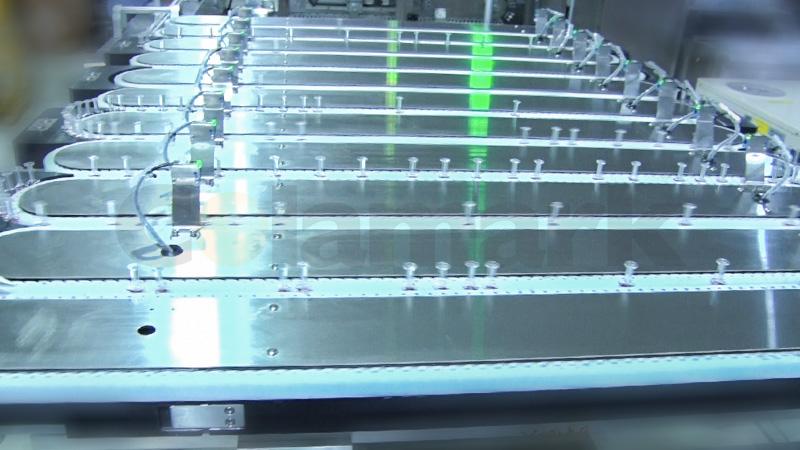

The line capacity is upto 300 syringes per minute consisting of Servo syringe Denester;

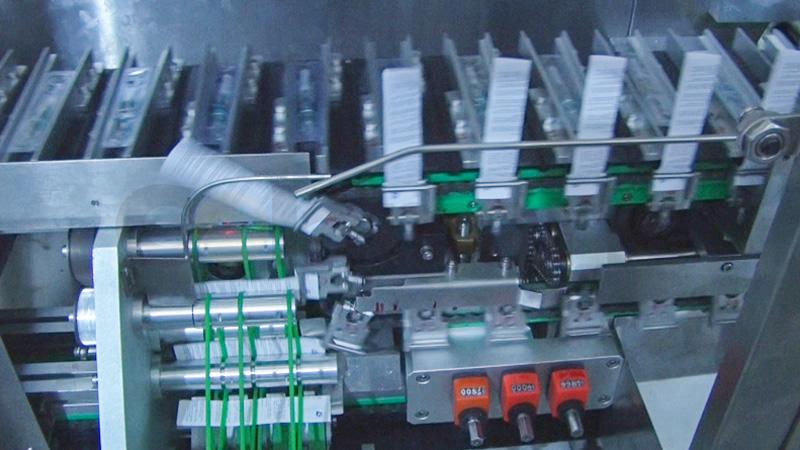

Plunger rod assembling, syringe labeling, Blister packing machine with inspection Servo driven cartoning machine.

L1 and L2 track and trace aggregation

The line capacity is upto 300 syringes per minute consisting of Servo syringe Denester;

Plunger rod assembling, syringe labeling, Blister packing machine with inspection Servo driven cartoning machine.

L1 and L2 track and trace aggregation